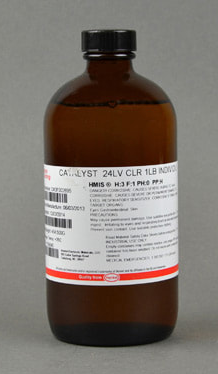

CATALYST 24LV电子组装/工业胶水/电子组装胶水/工业用胶

技术服务热线:021-51693135 / 021-22818476

Catalyst 24LV encapsulate is recommended for applications where high compressive stress is applied to encapsulated circuitry - as in deep ocean work.

This product will have a minimum effect on electronic circuit operation and shows negligible deformation and water absorption.

Storage Store product in the unopened container in a dry location. Storage information may be indicated on the product container labeling.

Optimal Storage: 18 to 25 °CDIRECTIONS FOR USE1.

Accurately weigh resin and hardener into a clean container in the recommended ratio.2. Mix thoroughly in the can in which it is received.3.

Liquid diluents can be supplied to lower viscosity at some sacrifice in properties.4. Pour mixture into cavity or mold.5. Mold release 122 S will prevent adhesion.

(Evacuation may be necessary to remove trapped air and is recommended for high quality embedment’s.

It is often convenient to remove the trapped air from the resin prior to pouring into mold, and then again evacuate briefly when the mold is filled).6. Allow to stand at room temperature for about 4 hours.

Removal from the mold prior to that time is possible if the casting is hard.7.

The filler will tend to float during storage. Premixing before use is required.

推荐使用催化剂24LV密封剂用于高压缩应力应用于封装电路的应用,如在深海工程中。

该产品对电子电路操作具有*小的影响,显示出可忽略的变形和吸水性。

Storage Store产品在未开封的容器中干燥处。存储信息可能在产品容器标签上显示。*佳存储:18至25°使用光盘1。

以推荐的比例精确称重树脂和固化剂成为清洁容器。

在收到的罐中彻底混合。可以提供液体稀释剂以降低粘度,同时牺牲一些特性。将混合物倒入腔或模具中。脱模122将防止粘附。

(疏散可能需要去除被困的空气,建议用于高质量的嵌入,通常在浇注模具之前将树脂中的空气从树脂中去除,然后在模具填充时再次抽出)。

允许在室温下静置约4小时。如果铸件很难,可以在此之前从模具中取出。

在储存期间,填料将倾向于浮动。使用前需要预混。 |

|

|