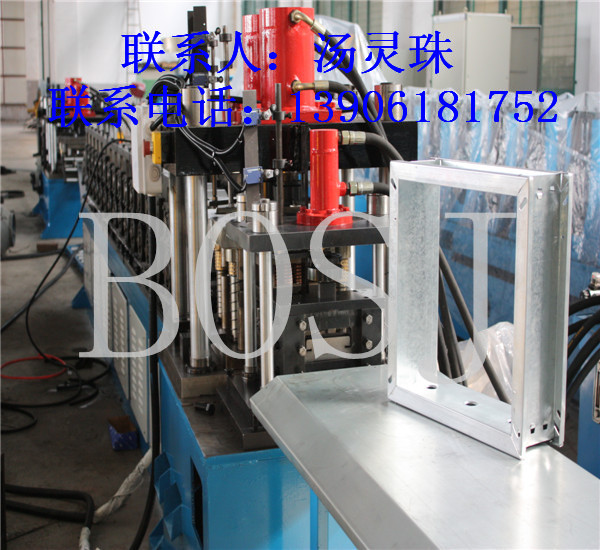

防火阀生产线设备

一、 成型工艺

放料——伺服送料——冲缺口及切断 ——成型——收料

二、 设备组成部件

设备主要由自动放料机、送料系统、冲缺口及切断、送料、成型主机、收料台、电器控制柜等部件组成。

三、 设备主要部件的技术参数:

1、 自动放料机

a、 负载能力:2吨

b、 处理卷料的内孔直径:490 - 510mm

c、 外径:≤1200mm

2、 伺服送料及冲缺角部分

a、 伺服电机:采用三菱伺服电机,电机功率:1.0kw

b、 冲缺模架为四导柱式

c、 冲模缺角模具材质: Cr12 。 淬火处理。

3、 传送料台:动力为0.37kw

4、 成型主机部分

a、 成型机架:12道次

b、 成型模具材质:GCr15,淬火处理,硬度为HRC56-62o

c、 电机:7.5kw变频电机。

5、 电器控制:PLC

Fireproof valve production line equipment

A, the molding process

Feeding - servo feed - piercing and cut - molding - receiving

Second, the equipment components

Equipment is mainly composed of automatic feeding machine, feeding system, notching and cutting, feeding, forming host, receiving station, electric control cabinet and other parts.

3, equipment, the technical parameters of main parts:

1, automatic feeding machine

A, the load capacity: 2 tons

B, the processing of coil diameter of bore: 490-510 - mm

C, outer diameter: 1200 mm or less

Part 2, servo feed and lack of Angle

A, servo motor: adopt mitsubishi servo motor, motor power: 1.0 kw

B and lack of die set for four guide pillar

C, die missing Angle mould material: Cr12. The quenching process.

3, send material platform: power is 0.37 kw

4, forming the host part

A, molding frame: 12 times

B, molding mold material: GCr15, quenching treatment, hardness of HRC56-62 DHS

C, motor: 7.5 kw variable frequency motor.

5, electrical control, PLC

温馨提示:【江阴博世杰防火阀成型设备】是由 |

|

|